Legacy Motorsports Brand Quietly Releasing MTB Brakes That Deliver originally appeared on BikeMag.

We’ve recently seen the branching of motorsports into mountain bike brakes, thanks to the collaboration between Brembo and Specialized Gravity. Still, these brakes have been a closely guarded secret, and they are not available outside of the team tents. Almost no details are available to the public, so they might as well still be in the prototyping stage.

But what happens when a motorsports brand takes a crack at mountain bike brakes that you can actually get your hands on? Well, HEL has done just that with the Advocate brakes, and we got all the details straight from the source. In this article, we'll answer all the questions you might have about this new and exciting MTB brake from the UK.

Photo: HEL MTB / Ian Lean

Photo: HEL MTB / Ian Lean Photo: HEL MTB / Ian Lean

Photo: HEL MTB / Ian LeanI first got wind of the HEL Advocate brakes towards the end of 2024, and what caught my attention was the brand's industrial approach to brake design, claims of high power, firm and consistent lever feel, and reduced brake fade, which is all too common with larger, 4-piston brakes. The HEL Advocate brakes are not only impressive on paper, but they are also visually appealing and are designed by a small team with a deep appreciation for well-engineered brakes that combat the current pitfalls of other big-ass brakes that are on the market. At $798.00 USD for a set, or $399.00 per side, they are also positioned to be stiff competition for other similar brakes on the market, but with a bit less fuss. For that, I have to tip my hat to the team at HEL.

Follow @Hel.MTBon Instagram to stay up to speed with all the developments.

"In a component as critical as brakes, we believe there should be no compromises, and the Advocate reflects that philosophy from start to finish."

From Motorsport to Mountain Bikes

In 1999, HEL Performance—commonly referred to as HEL (pronounced 'hell')—launched with a straightforward mission to establish a higher standard for braking performance. HEL swiftly evolved into a globally recognized, race-winning brand, thanks to its high-performance brake and clutch lines, which achieved great success across the motorsport industry. But things continue to evolve, and the passion has grown, but the objective remains the same. HEL is committed to providing the best stopping power. With roots in motorcycles and the automotive industry, they have set their sights on making some of the best mountain biking brakes on the market. The small team has a formula that has proven effective for applications in motorsport, and finding a way to translate this expertise into a reliable mountain bike brake was the mission as HEL launched the HEL Mountain Bike in June 2025.

Related: A New Mountain Bike Brake Is Coming in 2025, Here's What We Know

Following two years of discreet development by a dedicated two-person team of passionate riders with strong ties to HEL’s motorsport division, HEL Mountain Bike has softly introduced a new brake system to the market: the HEL Advocate, designed, developed, tested, manufactured, and meticulously hand-assembled entirely in-house in Exeter, Devon (UK).

By and for riders.Photo: HEL MTB / Ian Lean

By and for riders.Photo: HEL MTB / Ian LeanHEL handles the entire CNC machining process in-house for its host of brakes and parts. This gives the team complete control from start to finish, resulting in high-quality products that hit the mark of form and function that HEL demands. This approach ensures a finished product that functions to a higher standard and can withstand considerable abuse without faltering in performance, because braking shouldn't be something you ever need to second-guess.

Photo: HEL MTB / Ian Lean

Photo: HEL MTB / Ian Lean  Photo: HEL MTB / Ian Lean

Photo: HEL MTB / Ian LeanMeeting this level of quality requires a significant investment in every aspect of the business, and for HEL, the benefits far outweigh the costs. A focus on quality and craftsmanship is a trend in the mountain biking industry that consumers appreciate, and that is something that HEL has recognized from day one.

HEL has complete control over the design, production, finishing, and quality of its core product line, and it is not willing to compromise at any point in the process. Keeping everything in house means that HEL can offer riders reliable products and peace of mind, knowing that their brakes are designed, manufactured, and assembled to the highest standards, even if it means paying a bit more and waiting a bit longer. Even the raw stainless steel and aluminum used in production are sourced within the EU, ensuring enhanced quality assurance and traceability throughout the entire process—from raw chunks of metal to rideable brakes, HEL has control. This reduces the need to source and ship raw materials, lowering the overall carbon footprint of the brand.

Photo: HEL MTB / Ian Lean

Photo: HEL MTB / Ian Lean Photo: HEL MTB / Ian Lean

Photo: HEL MTB / Ian LeanHEL hasn't taken an entirely new approach to the way it operates, and this way of doing things is well respected, especially in the bike industry. Those in the know don't mind paying a bit more for a product that is well considered and meticulously assembled from start to finish. But what is HEL doing differently that makes the Advocate brakes stand out amongst the other bespoke or big-name brake options on the market? To answer this burning question, I reached out to Corey Partridge, the head of operations at HEL Mountain Bike, to get a better idea of what HEL is doing to make these brakes better than the rest.

Testing the product is part of the process...Photo: HEL MTB / Ian Lean

Testing the product is part of the process...Photo: HEL MTB / Ian Lean What Problems Do The Advocate Brakes Solve?

I didn't want to beat around the bush, and when I asked directly, "What are the pitfalls you saw with other brakes on the market that you wanted to address with the Advocate?" Corey gave me the following points that were music to my ears after spending some time on a few brakes that seriously struggle with all these issues.

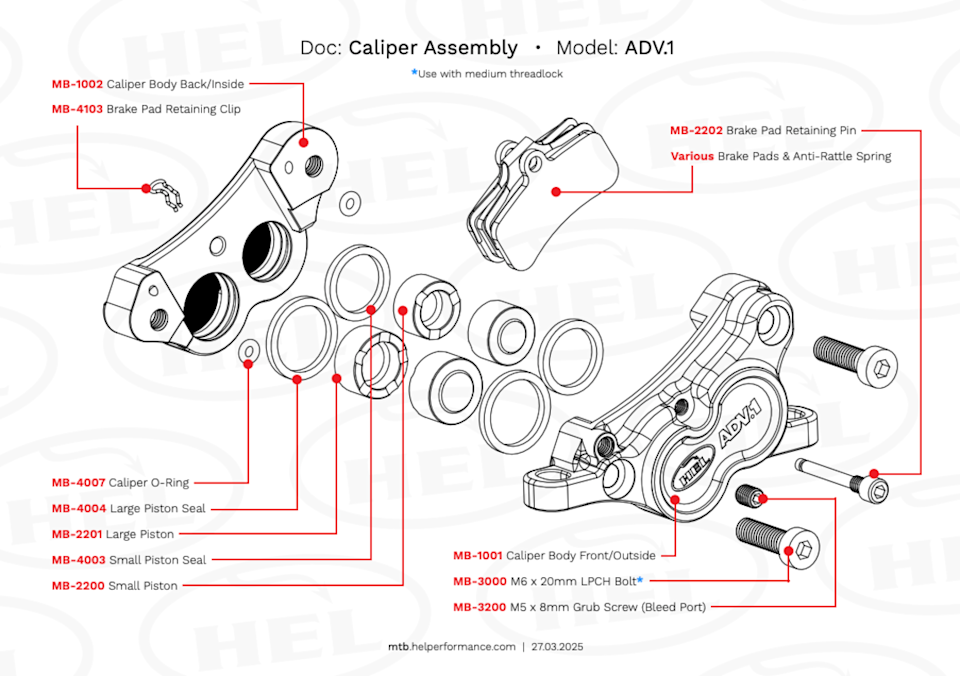

1. Build Quality

Far too many brakes on the market are outsourced purely for cost and speed, and it shows in the final product. At HEL, everything is done in-house - design, prototyping, machining, hand assembly, and testing - all under one roof by a small team of three. That gives us complete control over every detail and ensures the build quality meets our own high standards, not someone else’s compromise.

2. Consistent Performance

We wanted brakes that feel the same every single time you ride, and every single lever pull – no matter the demands or conditions. So we designed a brake that delivers a reliable, firm lever feel, throw, and power - whether you're out in the wet and cold, riding hot descents in Italy, or pushing long eMTB runs in Canada. As long as the system is bled properly using our procedure, the brakes don’t fade, the lever doesn’t pull to the bar, and performance is consistent. That’s been backed up by real-world customer feedback from riders around the globe.

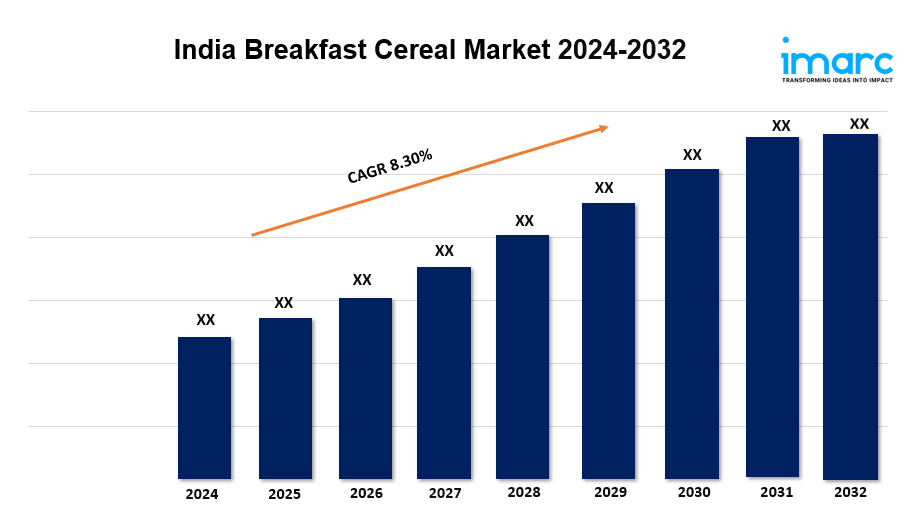

3. Accessibility and Transparency

We’ve built everything to be serviceable, clear, and rider-friendly. Every part is available as a spare, and our website hosts full exploded diagrams so you can see exactly how things go together, each individual SKU/part number, and the specification of the components. We've tried our best to avoid weird proprietary hardware - so if you lose a bleed screw on a ride, you can easily look up the size, head to a local bike shop or hardware store, and keep rolling. Plus, we're building a dealer network with spares stocked locally in each country. No mysteries, no waiting weeks for a tiny part - just brakes that are easy to understand, easy to keep on the trail, and maintain yourself.

Need tech details? HEL has you covered and then some.Photo: HEL MTB

Need tech details? HEL has you covered and then some.Photo: HEL MTBPowerful Brakes Need Powerful Hoses

Having gobs of stopping power at your fingertips is nothing if the hoses aren’t ready for the demands, and HEL MTB has taken this seriously. By shrinking down the exact same braided hose used in motorcycle and automotive applications, HEL MTB has developed a brake line that's more than ready to handle the power these brakes are generating. However, it’s more than just the performance efficiency of these brakes. These 3-layer stainless steel braided hoses are mated to the lever and caliper with an impressively user-friendly fitting that makes installation a breeze. Complete installation and service videos are linked at the bottom of this article for your reference, allowing you to see how impressive this system works together.

No olive, no barb, no stress.Photo: HEL MTB

No olive, no barb, no stress.Photo: HEL MTBHEL's unique two-piece fitting is something special that deserves attention. All you need is an 8mm spanner, no olives, no barbs, no fussing around - this is a prayer answered for hydraulic MTB brakes with DOT fluid. Pairing this unique system with absurdly durable stainless steel hoses means that you’ve got all the power on tap without compromise, but none of the drawbacks that have been associated with full-stainless braided hoses in the past. As is the case with everything from HEL MTB, this braided hose fitting kit is specifically designed and manufactured in Devon, England.

Burly fitting and hoses for some burly brakes.Photo: HEL MTB / Ian Lean

Burly fitting and hoses for some burly brakes.Photo: HEL MTB / Ian LeanThe hoses are composed of three layers: an inner PTFE core, a braided stainless steel layer, and an outer PVC layer. The stainless steel braid protects the internal high-flow PTFE core through which the brake fluid travels. Reinforcing the PTFE core stops hose expansion under high pressure and heat during prolonged braking. Thanks to the fittings and hose construction, the HEL Advocate delivers a consistent, firm, and responsive brake feel in all conditions. The outer PVC layer ensures they don’t saw through anything. It also allows for further color customization, enabling riders to color-match even more aspects of the bike, as mountain bikers often love matching parts. Unlike other stainless steel hose options, these hoses are just 5mm in diameter, which makes them easy to route internally. It's a win-win-win.

When you consider how all this comes together, it makes a lot of sense. Mountain bike brakes are under considerable demand these days, with rotors and calipers getting bigger and bigger, and eMTB becoming a massive chunk of the industry. The old way of doing things is being tested each year, and it's only a matter of time before it reaches a breaking point (pun intended). It makes sense that technology would trickle down from motorcycle applications, and the HEL Advocate brakes are a perfect example of how mountain bike brakes are evolving with help from other industries.

Q&A

What was the driving inspiration for HEL to design a MTB brake?

Corey Partridge: The idea had been brewing for quite a while. With deep roots in the motorsport industry, we’ve always had customers, distributors, and even staff who are passionate mountain bikers - and they kept asking. It was also a natural evolution for the business with expansion and diversification. The HEL Mountain Bike division was born from within – our team were, and some are still active in the motorsport side of things, so other than myself the team are machinists or designers who manufacture our superbike or motorcycle brake systems.

So we weren’t starting from scratch; we had the knowledge, the people, and the passion to do it right.

Photo: HEL MTB / Ian Lean

Photo: HEL MTB / Ian LeanHow has HEL's motorsport heritage helped in the design of these brakes?

Corey Partridge:We use some crossover components from our superbike brake systems, or very close and miniature versions of the components. The Advocate caliper, for example, shares the same free-flow internal fluid channel layout as our superbike calipers, along with similar piston designs, seal types, and finishing processes. It’s a product built on proven performance DNA - refined for the trail.

If the tech is good enough for superbikes, it's good enough for MTBs...Photo: HEL Performance

If the tech is good enough for superbikes, it's good enough for MTBs...Photo: HEL Performance The HEL Solid Billet Finger Brake for MotoPhoto: HEL Performance

The HEL Solid Billet Finger Brake for MotoPhoto: HEL PerformanceEven though HEL Mountain Bike is a small, dedicated team, we’re lucky to work shoulder-to-shoulder with experienced engineers, ex-racers, and mechanics from the HEL Performance family. These are people who’ve spent years designing, building, riding, and supporting our race-winning motorcycle and automotive systems, and they’re always willing to dip-in and get involved. During development, that in-house collaboration helped us solve complex design challenges and push performance further than we could have on our own.

NDS doesn't matter when it's those brakes that stand out.Photo: HEL MTB / Ian Lean

NDS doesn't matter when it's those brakes that stand out.Photo: HEL MTB / Ian Lean In your opinion, what makes the HEL Advocate Brakes stand out among brakes from other brands?

Corey Partridge:The HEL Advocate brakes are designed to be robust, consistent, and high quality. They deliver a distinct lever feel that’s confident and predictable, ride after ride. And when it comes to maintenance, we’ve kept things open and transparent - no proprietary tools, no hidden tech. If you’ve got the right tools and some mechanical confidence, you can service them yourself using our guides and videos. That transparency and accessibility matter to us.

We’re not trying to reinvent braking, or the wheel. Our goal is simple: build a brake system that riders can trust, made entirely under our own roof by people who care and, most importantly, ride the products we make. Every part is machined, assembled, and tested in-house by a team of riders and 2-wheel nutters. In a component as critical as brakes, we believe there should be no compromises, and the Advocate reflects that philosophy from start to finish.

Photo: HEL MTB / Ian Lean

Photo: HEL MTB / Ian Lean Photo: HEL MTB / Ian Lean

Photo: HEL MTB / Ian LeanTech Details & Price

Nothing is hidden here, and HEL offers all the details you could ever need to service and maintain your Advocate brakes.

MSRP: $798.00 USD for a set, or $399.00 USD per side.

Available in 16 standard color combinations: Black, Silver, Bronze, or Grey. HEL is soon launching a realistic 3D interactive custom brake builder towards the end of the year, allowing an addition of 3 unique colours: Red, Purple, and Blue.

Master Cylinder and Lever

These are some burly boys.Photo: HEL MTB / Ian Lean

These are some burly boys.Photo: HEL MTB / Ian LeanType: Axial

Piston Size: 10mm ⌀

Piston Material: Stainless Steel

Lever Adjustment: Tool-Free, 20-Point Click

Lever Span: 35mm (Min. - Max.)

Bleed Port: M5 x 0.8mm

Fluid Compatibility: DOT 5.1 Only

Weight (Excl. Hose): 155g

Finish: Hard Anodised

Material (Main): 6082-T6 Billet Aluminium

Material (Other): Stainless Steel

Caliper

Available in Silver, Black, Grey, and Bronze, for now.Photo: HEL MTB / Ian Lean

Available in Silver, Black, Grey, and Bronze, for now.Photo: HEL MTB / Ian Lean Fluid Design: Free-Flow

Piston Quantity: 4

Piston Diameter: 2x 17mm ⌀ & 2x 15mm ⌀

Piston Design: Solid, Castellated Top

Piston Material: Stainless Steel

Pad Compatibility: HEL Advocate / Shimano Saint, XT, XTR / Galfer FD426 /TRP DHR EVO

Rotor Compatibility Diameter: 180mm / 203mm / 220mm

Rotor Compatibility Thickness: 1.8mm / 2.0mm / 2.3mm

PM Adapter Compatibility: HEL Advocate / Universal

Bleed Port: M5 x 0.8mm

Fluid Compatibility: DOT 5.1 Only

Weight (Excl. Pads & Hose): 105g

Finish: Hard Anodised

Material (Main): 6082-T6 Billet Aluminium

Material (Other): Stainless Steel

Hose & Fit Kit

Photo: HEL MTB / Ian Lean

Photo: HEL MTB / Ian Lean Photo: HEL MTB / Ian Lean

Photo: HEL MTB / Ian LeanConstruction: 3-Layer Braided Stainless Steel

External Diameter: 5.0mm / 0.19" ⌀

Frame Compatibility: Internal & External Routing*

Internal Material (Core): PTFE

External Material (Overbraid): Stainless Steel 304

External Material (Outer): PVC (Transparent or Coloured)

Colour Options: Various

Hose Fitting Solution: 2-Piece

Hose Fitting Compatibility: HEL Advocate

Hose Fitting Material: Stainless Steel

Supplied Hose Length: 2.7 metres (Uncut)

Tools for Service

To install, bleed, and dial in your HEL Advocate brakes, you'll need the following tools and accessories. To make things even easier, HEL has these comprehensive guides for installing and bleeding the Advocate brakes.

Caliper Bleed Block (Supplied)

Allen Key: 2.5mm / 3mm / 4mm / 5mm

Open-End Spanner: 8mm (2)

Hose Cutter or Side-Cutting Plier

Hand Pick/Poking Tool

Nitrile or Latex Gloves

Wiping Cloths/Blue Roll

Isopropyl Alcohol (Recommended) or Disc Brake Cleaner

Brake Bleed Kit: M5 x 0.8mm (Recommended: SRAM Pro Bleed Kit or Park Tool BKD-1.2)

Available Now Atmtb.helperformance.com

This story was originally reported by BikeMag on Jul 23, 2025, where it first appeared.